MDF, also known a Medium Density Fiberboard, is a synthetic product comprised essentially of recycled wood particles and wood fibers held together by a resin binder or wax and compressed to form flat panels under extremely high temperatures.

Medium-density fiberboards are relatively heavier than lumber and plywood, although, this is largely due to their composition being a lot denser than the other mentioned products. This, of course, is something you should keep at the back of your mind if you intend to build with this material.

Aside from this minor setback, medium density fiberboard is an admirable eco-friendly building material, some of the reasons being that it bonds easily with glue and can be secured to any surface with very minimal effort and it also has low susceptibility to fracture.

See also: Best cabinet for your kitchen: Plywood Kitchen Cabinets Or Stainless Steel Cabinets

Working with MDF boards

If you’re going to rout MDF edges or surfaces, it’s in your best interest to do so outdoors as most MDF sheets comprise softwood residuals which tend to create a dust storm when cut. Also, it would be wise to wear a respirator when sawing through or sanding this material to protect yourself from exposure to the resins and fine dust of which this product is composed.

Even with its remarkable qualities, MDF is known for its vulnerability to moisture, more so for the unfinished kinds, these tend to lose strength and swell with time after coming in contact with water, unlike plywood.

Since medium density fibreboard [fiberboard] (MDF) comes in various colors and is relatively easy to paint, it’s commonly used for visible applications, like in the production of kitchen cabinets. Unlike MDF, particleboard isn’t quite as ideal for painting, which is one of the major reasons why It’s so often used in concealed locations around the house and usually serves as an underlayment for other types of flooring.

Occasionally, during the production of this material, additives are introduced to minimize its susceptibility to moisture, add a level of reinforcement and impart some additional characteristics. Generally, the surfaces of medium-density fiberboard products are smooth, uniform, and void of any kind of knots or grain patterns, making them super easy to work with.

It is very easy to mistake MDF for several other materials, including solid wood, plywood, and melamine. Here’s how to differentiate MDF from other cabinet materials.

How to make MDF water resistant

For this task, you’ll need a top-quality sealant or wood varnish capable of withstanding the threat of humidity or moisture. These usually come in a wide variety of colors, allowing you the privilege of improving your MDF appearance while adding a layer of protection at the same time.

Once you’ve acquired the ideal sealant or solvent-based primer, you simply have to cover the entire surface of your MDF and you’re all set. You’ll find this procedure to be worth the effort if you intend to apply your MDF in areas such as the bathroom or kitchen, as it will save you the cost and hassle of constant repairs.

Are there poisonous chemicals in MDF?

When this question is asked, people are basically referring to the formaldehyde compound present in medium-density fiberboards which is a well-known human carcinogen. This, of course, has to do with the various studies connecting formaldehyde to certain health-related issues, although if you’re to consider it from this angle, there are a few other things to take note of as well.

Firstly, there are strict government restrictions on the level of chemicals used in manufacturing MDF, especially in the case of formaldehyde. The limitation on the amounts of this material used for MDF essentially serves as a buffer aimed at reducing any significant health risks associated with this chemical.

Secondly, the off-gassing or dispersal of this chemical usually takes place during the production of MDF. What this means is that by the time the MDF furniture reaches the various home centers where they’ll be sold, the off-gassing process would have been long concluded thereby rendering the furniture completely safe.

Advantages of MDF for Cabinets

While MDF is often mistaken for particleboard due to the similarity of their appearance, a notable distinction between these two wooden materials is that, unlike the latter, MDF cuts exceedingly well and its smooth texture makes it the more ideal option for paintwork.

The following are some of the upsides of using MDF-made furniture:

- MDF is an inexpensive material, which means that acquiring furniture pieces made with this material will be a lot cheaper compared to hardwood options.

- MDF can easily be painted over with just about any color, while hardwood isn’t quite as easy to paint and isn’t guaranteed to accept every color type.

- MDF typically has knot-free, smooth surfaces.

- The chemical composition of MDF causes it to repel pests such as termites.

- Unlike solid wood, MDF isn’t quite as susceptible to contraction or expansion as a result of heat or humidity.

- It’s a whole lot easier to cut and shape MDF than solid wood. This opens up possibilities for more exquisite and elaborate designs.

- It doesn’t take much to attach wood veneers to MDF and the way they blend effortlessly helps portray the same appeal of genuine solid wood.

You should also see: Particleboard Or Plywood Cabinets, Which Is Better For The Kitchen?

Disadvantages of MDF Furniture

- As we’ve discussed earlier concerning the production of this material, MDF dispels some levels of formaldehyde, although we also made it clear that every last bit of this chemical is dissipated post-production. More so, when the surface of the finished product is painted over.

- Medium-density fiberboard requires high maintenance; what this means is that if this material chips or cracks it would require a great deal of effort to repair or cover the damages which will also come at a cost if you’ll be hiring a professional.

- Exposure to water can result in swelling.

Are you considering a kitchen remodel or you are planning for the best kitchen cabinets for your US home? Here’s an article you must read to avoid making mistakes that can cost you money, time, comfort, and peace: What’s the best material for kitchen cabinets in the USA?

Is moisture-resistant MDF solid wood?

These are specifically sheet materials made out of compressed wood fibers, merged with resins. They undergo the same processing as standard MDF, except for the added moisture resistant properties which allow them to be used without fear of damage in areas subject to humidity or moisture. As such, they are not solid wood but have some of the characteristics of solid wood.

Important safety precautions to follow during the construction and installation process of MDF

Medium-density fiberboards can be harmful if safety requirements aren’t adhered to. In this section, we’ll be discussing some key points to keep in mind when working with this engineered wood product.

Normally, when medium density fiberboards are cut or sanded the urea-formaldehyde compound is automatically released into the air. Due to the health complications, this compound is capable of causing, proper ventilation is of the essence, facemasks are also a requirement when cutting or sanding this material whether personally or by employing machinery.

Aside from the formaldehyde compound, the fine powder dispersed into the air when cutting MDF is also to be avoided. Although the particles aren’t nearly as harmful as the formaldehyde compound, it can be quite inconvenient to inhale the sawdust as it can lead to lung irritation. Hence, we recommend wearing goggles and masks while working with this material.

While it’s possible to use nails and screws on MDF, the same as any other wood product, there is however a seemingly high possibility of split edges occurring. To avoid this, use the nails at a minimum distance of about 20 to 22mm away from the edge of the MDF board or drill a pilot hole deep into the inner layers of the wood before nailing.

Pilot holes are also referred to as nail holes and are quite helpful when using MDF since they prevent the edge of the wood from splitting as a result of extreme pressure. Since MDF tends to release formaldehyde, ensure that the sheets are properly sealed. Also, it wouldn’t be a bad idea to add a coat of paint to the surface of the sheets to effectively contain the formaldehyde compound.

The different MDF wood variants

MDF panels are available in three varieties categorized mainly by their specific features, which include fire resistance, moisture resistance, and ultra-light MDF boards.

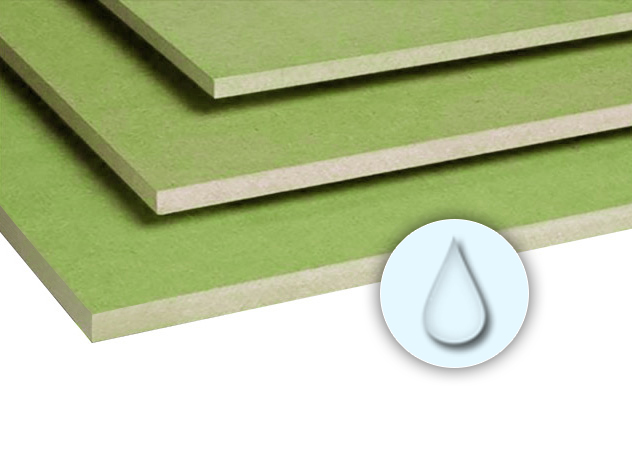

Water-resistant MDF

As the name implies, moisture-resistant MDF boards are ideal for places that tend to get wet such as bathrooms. These MDF boards are identifiable by the green stamps on their edges.

Fire retardant MDF boards

Fire retardant MDF boards are most commonly used in the kitchen and for obvious reasons. These boards are often marked with blue or red stamps on their edges.

Ultra-light MDF boards

Ultra-light MDF boards on the other hand weigh about 30% lesser than regular MDF boards, these woods are best suited for making furniture due to their lightweight feature and extremely smooth surface.

What are laminate MDF boards?

These are technically MDF boards made with a unique surface finish. This MDF board variant is generally regarded as a much better substitute to plywood. Their smooth and refined laminate coating provides an added layer of support to the fiberboard itself, rendering it extremely durable and scratch-resistant.

Laminate MDF boards are often used for making cupboard shutters, tabletops, window sills, doors, panels, and furniture making.

Conclusion

MDF sheets were introduced in an attempt to create substitutes for natural wood and have built up an unassailable reputation as a sustainable building material in recent years.

Asides from being a sturdy material, MDF also allows a great deal of flexibility for complex designs. When these boards are produced and installed properly, they prove to be one of the best composite wood materials for modular kitchens.

Do you want to become one of Choice Cabinet’s trusted cabinet dealers? Send us a message today and let us help you achieve success selling the best cabinets to homeowners in Ohio and the US at large.